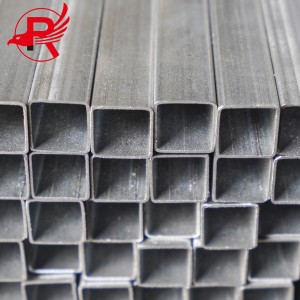

Tiùb stàilinn ghalbhanaichte ceàrnagach ASTM Standard St37

Pìob ceàrnagach ghalbhanaichte, ris an canar cuideachd pìob stàilinn ghalbhanaichte, air a roinn ann an dà sheòrsa ghalbhanaichte teth-tumtha agus ghalbhanaichte dealain, tha sreath ghalbhanaichte teth-tumtha tiugh, le còmhdach èideadh, greamachadh làidir, beatha seirbheis fhada agus buannachdan eile. Tha cosgais electrogalvanization ìosal, chan eil an uachdar glè rèidh, agus tha an aghaidh creimeadh mòran nas miosa na pìob ghalbhanaichte teth-tumtha.

Pìob ghalbhanaichte fuar: Tha pìob ghalbhanaichte air a ghalbhanachadh fuar air a ghalbhanachadh le dealan, agus tha an ìre de ghalbhanachadh glè bheag, dìreach 10-50 gram gach meatair ceàrnagach, agus tha an aghaidh creimeadh aige fhèin gu math eadar-dhealaichte bho phìob ghalbhanaichte teth. Chan eil a’ mhòr-chuid de ionadan cinneasachaidh phìoban ghalbhanaichte àbhaisteach a’ cleachdadh ghalbhanachadh dealain (platadh fuar) a thaobh càileachd. Chan eil ach iomairtean beaga le uidheamachd seann-fhasanta a’ cleachdadh ghalbhanachadh dealain, agus tha a’ phrìs an ìre mhath saor.

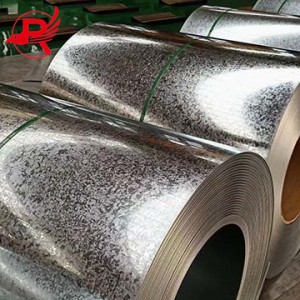

Pìob ghalbhanaichte teth-tumte

Bidh am meatailt leaghte ag ath-fhreagairt leis a’ mhaitris iarainn gus sreath aloidh a chruthachadh, gus am bi am maitrís agus an còmhdach air an cur còmhla. Is e galbhanachadh teth-tumaidh a bhith a’ picilte a’ phìob stàilinn an toiseach, gus an ogsaid iarainn a thoirt air falbh bho uachdar na pìoba stàilinn, às deidh a picilte, tro fhuasgladh uisgeach clòraid ammonium no clòraid sinc no tanca fuasgladh uisgeach measgaichte clòraid ammonium agus clòraid sinc airson a ghlanadh, agus an uairsin a-steach don tanca platadh teth-tumaidh. Tha buannachdan aig galbhanachadh teth-tumaidh le còmhdach èideadh, greamachadh làidir agus beatha seirbheis fhada. Bidh a’ mhòr-chuid de na pròiseasan anns a’ cheann a tuath a’ gabhail ri pròiseas ath-lìonadh sinc airson pìob coilich dhìreach crios ghalbhanaichte.

Pìob ghalbhanaichte fuar

Tha galbhanachadh fuar na ghalbhanachadh dealain, tha meud a’ ghalbhanachaidh glè bheag, dìreach 10-50g/m2, agus tha an aghaidh creimeadh aige fhèin gu math eadar-dhealaichte bho phìob ghalbhanachadh teth. Chan eil a’ mhòr-chuid de luchd-saothrachaidh phìoban galbhanachaidh cunbhalach a’ cleachdadh galbhanachadh dealain (platadh fuar) gus dèanamh cinnteach à càileachd. Chan eil ach iomairtean beaga le uidheamachd seann-fhasanta a’ cleachdadh galbhanachadh dealain, agus gu dearbh, tha na prìsean aca an ìre mhath saor. San àm ri teachd, cha tèid pìoban galbhanachaidh fuar a chleachdadh mar phìoban uisge is gas.

Pìob stàilinn ghalbhanaichte teth-tumadh

Bidh ath-bheachdan fiosaigeach is ceimigeach iom-fhillte a’ tachairt eadar bun-stuth an tiùba stàilinn agus an amar leaghte gus sreath teann de aloidh sinc-iarann a chruthachadh a tha an aghaidh creimeadh. Tha an sreath aloidh air a thoirt a-steach leis an t-sreath sinc fìor-ghlan agus maitrís na pìoba stàilinn. Mar sin, tha an aghaidh creimeadh aige làidir.

Às dèidh leasachadh phìoban stàilinn teth-ghalbhanaichte anns na 1960an gu na 1970an, chaidh càileachd nan toraidhean a leasachadh gu mòr. Bho 1981 gu 1989, fhuair iad duaisean airgid nàiseanta bho Mhinistrealachd Mheatailtearachd airson toraidhean àrd-inbhe, agus mheudaich an cinneasachadh thar grunn bhliadhnaichean. Ann an 1993, b’ e còrr is 400,000 tunna an toradh, agus ann an 1999, b’ e còrr is 600,000 tunna an toradh, agus chaidh an às-mhalairt gu Ear-dheas Àisia, Afraga, na Stàitean Aonaichte, Iapan, agus dùthchannan agus roinnean na Gearmailt. Bithear a’ cleachdadh phìoban teth-ghalbhanaichte sa mhòr-chuid mar phìoban uisge agus gas, agus is iad na sònrachaidhean cumanta +12.5 ~ +102 mm. Às dèidh nan 1990an, air sgàth aire na stàite do dhìon na h-àrainneachd, tha smachd air iomairtean truaillidh àrd a’ sìor fhàs nas teinne, tha e duilich fuasgladh fhaighinn air na “trì sgudail” a chaidh a chruthachadh ann an cinneasachadh phìoban ghalbhanaichte teth-tumadh. Còmhla ri leasachadh luath phìoban tàthaichte stàilinn gun staoin, pìoban PVC agus pìoban co-dhèanta, a bharrachd air an stàit gus cleachdadh stuthan togail ceimigeach a bhrosnachadh, tha cleachdadh phìoban stàilinn ghalbhanaichte air a chuingealachadh, a’ toirt buaidh mhòr air leasachadh phìoban tàthaichte ghalbhanaichte teth-tumadh. Tha Beam agus crìochan air a bhith ann, agus tha pìoban tàthaichte ghalbhanaichte teth-tumadh air an leasachadh gu slaodach nas fhaide air adhart.

Pìob stàilinn ghalbhanaichte fuar

’S e còmhdach dealain a th’ anns an t-sreath sinc, agus tha an t-sreath sinc air a chòmhdach gu neo-eisimeileach leis a’ mhaitris phìoba stàilinn. Tha an t-sreath sinc tana, agus tha an t-sreath sinc ceangailte gu sìmplidh ri maitrís a’ phìoba stàilinn agus tha e furasta tuiteam dheth. Mar sin, tha an aghaidh creimeadh bochd. Ann an togalaichean còmhnaidh ùra, tha e toirmisgte pìoban stàilinn ghalbhanaichte fuar a chleachdadh mar phìoban solar uisge.

Iarrtas

Leis gu bheil pìob ceàrnagach ghalbhanaichte air a ghalbhanachadh air pìob ceàrnagach, tha raon tagraidh pìoba ceàrnagach ghalbhanaichte air a leudachadh gu mòr an taca ri pìob ceàrnagach. Tha e air a chleachdadh sa mhòr-chuid ann am ballachan cùirteir, togail, saothrachadh innealan, pròiseactan togail stàilinn, togail shoithichean, camagan gineadh cumhachd na grèine, innleadaireachd structar stàilinn, innleadaireachd cumhachd, ionadan cumhachd, innealan àiteachais is ceimigeach, ballachan cùirteir glainne, chassis chàraichean, puirt-adhair agus mar sin air adhart.

| Ainm Bathar | Pìob Stàilinn Ceàrnagach Galvanised | |||

| Còmhdach sinc | 35μm-200μm | |||

| Tiughas Balla | 1-5MM | |||

| Uachdar | Ro-ghalbhanaichte, ghalbhanaichte teth-bhogtha, ghalbhanaichte le dealan, dubh, peantaichte, snàthaichte, gràbhaladh, socaid. | |||

| Ìre | Q235, Q345, S235JR, S275JR, STK400, STK500, S355JR, GR.BD | |||

| Fulangas | ±1% | |||

| Olaichte no gun ola | Gun ola | |||

| Ùine Lìbhrigidh | 3-15 latha (a rèir an fhìor thunnais) | |||

| Cleachdadh | Innleadaireachd catharra, ailtireachd, tùir stàilinn, gàrradh-shoithichean, sgafaill, strutan, pìleagan airson casg a chuir air sleamhnagan-talmhainn agus eile structaran | |||

| Pasgan | Ann am pasganan le stiall stàilinn no ann am pacaidean sgaoilte, neo-fhighte no a rèir iarrtas luchd-ceannach | |||

| MOQ | 1 tunna | |||

| Teirm Pàighidh | T/T | |||

| Teirm Malairt | FOB, CFR, CIF, DDP, EXW | |||

Mion-fhiosrachadh

C: An e neach-dèanamh a th’ ann an UA?

A: 'S e, tha sinn nar saothraiche. Tha an fhactaraidh againn fhèin suidhichte ann am Baile Tianjin, Sìona.

C: An urrainn dhomh òrdugh deuchainn fhaighinn dìreach beagan thunnaichean?

A: Gu dearbh. Is urrainn dhuinn an luchd a chuir air falbh dhut le seirbheis LCL. (Nas lugha de luchd container)

C: Ma tha sampall an-asgaidh?

A: Sampall an-asgaidh, ach pàighidh an ceannaiche airson a’ chosgais bathair.

C: A bheil thu nad sholaraiche òir agus a bheil thu a’ dèanamh gealltanas malairt?

A: Tha sinn air a bhith nar solaraiche òir seachd bliadhna agus a’ gabhail ri gealltanas malairt.